Mig Welding Sheet Metal Settings

Mig Welding Sheet Metal Settings - Mild steel, aluminum, and stainless or nickel alloys are the most used metals with the mig process. Web to weld sheet metal with solid wires, use electrode positive (ep, or reverse polarity). Web the wire you choose, the shielding gas, and the machine settings all depend on the material. When good results are achieved, record the. Web find below the mig welding sheet metal settings chart which displays the recommended settings. Joint design, position and other factors affect results and settings. Web |starting from scratch and setting up two different mig welders to weld sheet metal Web the following basic mig welding settings are for welding steel with solid wire.

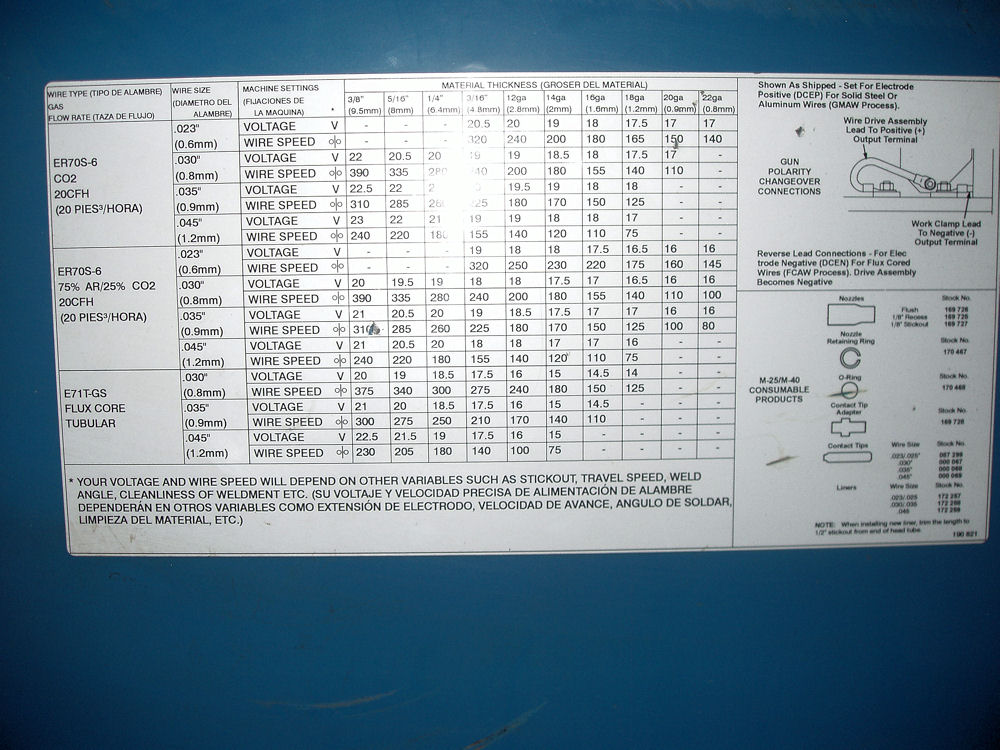

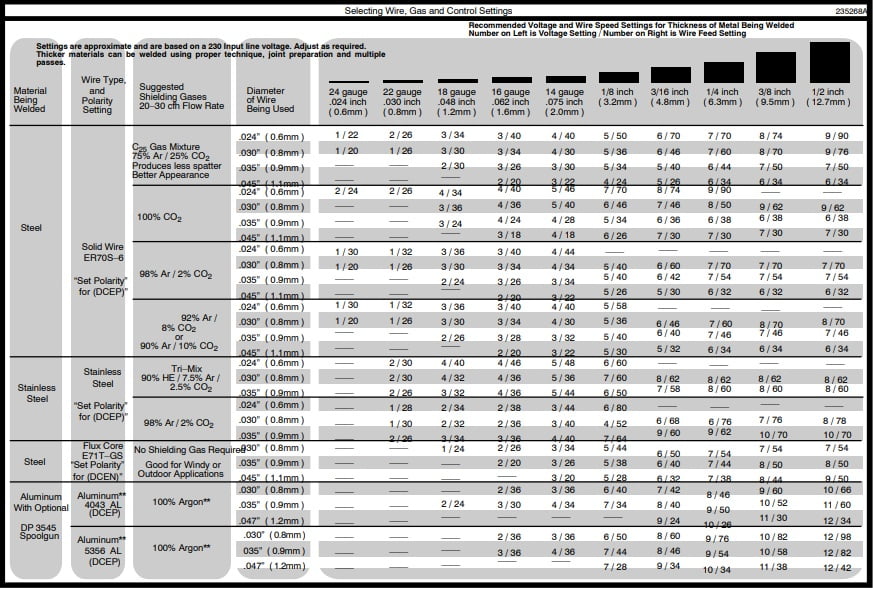

Web find below the mig welding sheet metal settings chart which displays the recommended settings. Web the wire you choose, the shielding gas, and the machine settings all depend on the material. Joint design, position and other factors affect results and settings. Web to weld sheet metal with solid wires, use electrode positive (ep, or reverse polarity). When good results are achieved, record the. Web the following basic mig welding settings are for welding steel with solid wire. Mild steel, aluminum, and stainless or nickel alloys are the most used metals with the mig process. Web |starting from scratch and setting up two different mig welders to weld sheet metal

Web the wire you choose, the shielding gas, and the machine settings all depend on the material. Web to weld sheet metal with solid wires, use electrode positive (ep, or reverse polarity). Web find below the mig welding sheet metal settings chart which displays the recommended settings. Web the following basic mig welding settings are for welding steel with solid wire. Web |starting from scratch and setting up two different mig welders to weld sheet metal Mild steel, aluminum, and stainless or nickel alloys are the most used metals with the mig process. When good results are achieved, record the. Joint design, position and other factors affect results and settings.

Beginning to MIG Weld Welding tips, Welding flux, Diy welding

Web |starting from scratch and setting up two different mig welders to weld sheet metal Web the wire you choose, the shielding gas, and the machine settings all depend on the material. When good results are achieved, record the. Mild steel, aluminum, and stainless or nickel alloys are the most used metals with the mig process. Web to weld sheet.

7 Tips for How to MIG Weld Aluminium Welding Mastermind

Web find below the mig welding sheet metal settings chart which displays the recommended settings. Joint design, position and other factors affect results and settings. Mild steel, aluminum, and stainless or nickel alloys are the most used metals with the mig process. Web the wire you choose, the shielding gas, and the machine settings all depend on the material. Web.

My mig welds on 14ga sheet metal Sheet metal, Metal, Welding

Mild steel, aluminum, and stainless or nickel alloys are the most used metals with the mig process. Web to weld sheet metal with solid wires, use electrode positive (ep, or reverse polarity). Web find below the mig welding sheet metal settings chart which displays the recommended settings. When good results are achieved, record the. Joint design, position and other factors.

Setting Up Your MIG Welder For Sheet Metal YouTube

Web to weld sheet metal with solid wires, use electrode positive (ep, or reverse polarity). Web the wire you choose, the shielding gas, and the machine settings all depend on the material. When good results are achieved, record the. Web find below the mig welding sheet metal settings chart which displays the recommended settings. Joint design, position and other factors.

MIG Welding How to MIG Weld, Process Overview and Machine Set Up

Web the following basic mig welding settings are for welding steel with solid wire. Web |starting from scratch and setting up two different mig welders to weld sheet metal Web the wire you choose, the shielding gas, and the machine settings all depend on the material. Mild steel, aluminum, and stainless or nickel alloys are the most used metals with.

Mig Welding Troubleshooting Chart

Web find below the mig welding sheet metal settings chart which displays the recommended settings. Joint design, position and other factors affect results and settings. Web the following basic mig welding settings are for welding steel with solid wire. Web |starting from scratch and setting up two different mig welders to weld sheet metal Web to weld sheet metal with.

Mig Welding Technique for Thin Metal Metal welding, Metal working

Web |starting from scratch and setting up two different mig welders to weld sheet metal Web to weld sheet metal with solid wires, use electrode positive (ep, or reverse polarity). When good results are achieved, record the. Web the following basic mig welding settings are for welding steel with solid wire. Joint design, position and other factors affect results and.

Millermatic 252 Setting Chart

Web to weld sheet metal with solid wires, use electrode positive (ep, or reverse polarity). When good results are achieved, record the. Web find below the mig welding sheet metal settings chart which displays the recommended settings. Web the following basic mig welding settings are for welding steel with solid wire. Mild steel, aluminum, and stainless or nickel alloys are.

How To Weld Sheet Metal TIG / MIG / Welding Thin Metal

Joint design, position and other factors affect results and settings. Web find below the mig welding sheet metal settings chart which displays the recommended settings. When good results are achieved, record the. Web the wire you choose, the shielding gas, and the machine settings all depend on the material. Web the following basic mig welding settings are for welding steel.

Welding Thin Sheet Metal With MIG

Web the wire you choose, the shielding gas, and the machine settings all depend on the material. When good results are achieved, record the. Joint design, position and other factors affect results and settings. Mild steel, aluminum, and stainless or nickel alloys are the most used metals with the mig process. Web to weld sheet metal with solid wires, use.

Web The Wire You Choose, The Shielding Gas, And The Machine Settings All Depend On The Material.

When good results are achieved, record the. Web to weld sheet metal with solid wires, use electrode positive (ep, or reverse polarity). Joint design, position and other factors affect results and settings. Web the following basic mig welding settings are for welding steel with solid wire.

Web |Starting From Scratch And Setting Up Two Different Mig Welders To Weld Sheet Metal

Web find below the mig welding sheet metal settings chart which displays the recommended settings. Mild steel, aluminum, and stainless or nickel alloys are the most used metals with the mig process.