Form Fill Seal

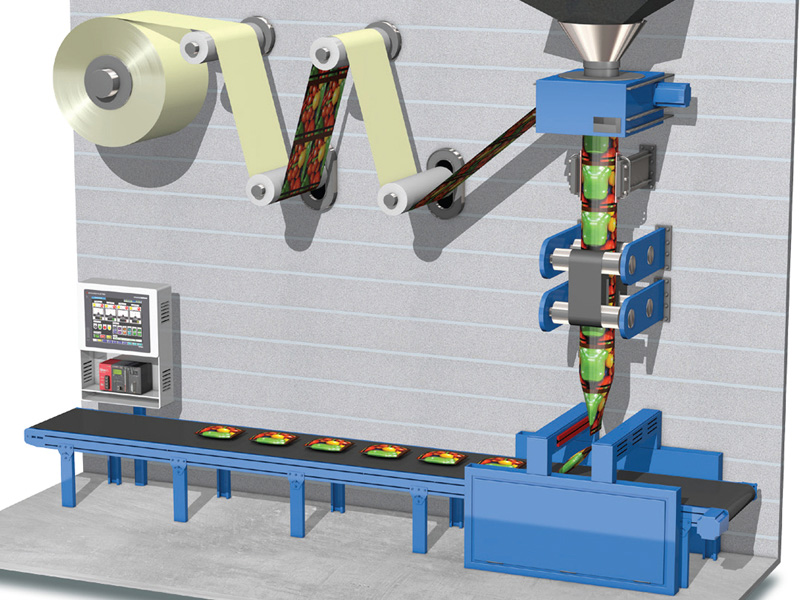

Form Fill Seal - Premium ffs flat film ; The film is pulled off the roll by belts and is then transferred to a forming tube. Our hamer brand of large format horizontal form, fill & seal bagging automation has set the industry standard for over 30 years. Ultra speed ffs tubular film ; Vertical form fill seal solutions. Premium ffs tubular film ; Ffs offers cost savings over conventional aseptic processing in glass. Web form fill and seal operation. It is capable of forming and filling bags measuring 2.5” x 3” to 8” x 14” with volumes ranging from.5 oz to 5 lb, at speeds up to 60 cycles per minute with a pneumatic jaw. Web heavy duty bags & form fill seal.

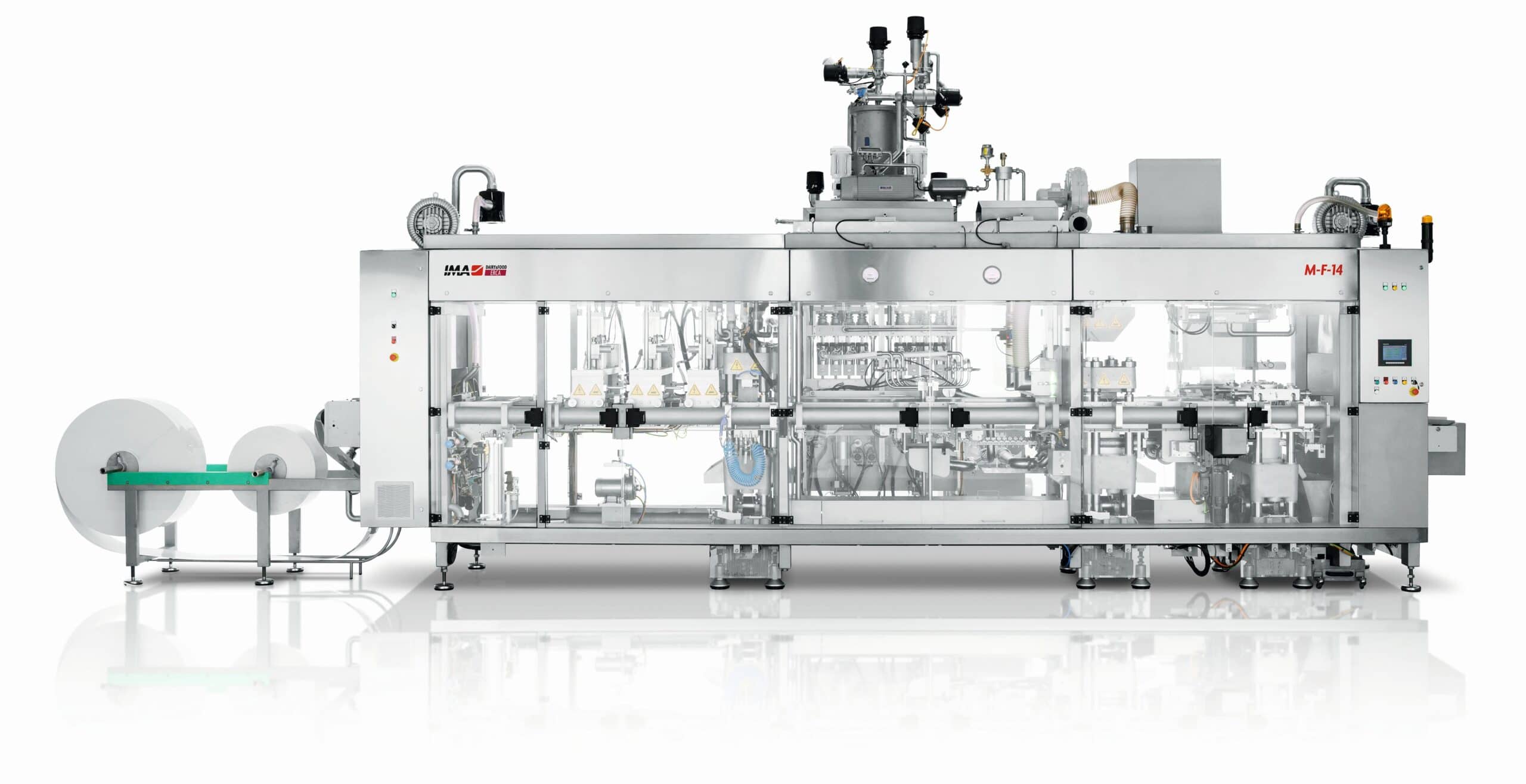

The most versatile on the market this solution is suitable for all commercially available resins, such as ps, pp, pet and pla. Matrix can help you find your flexible packaging solution. Web form fill seal (ffs) technology is an automated computer operated technology, to prepare sterile products. Web heavy duty bags & form fill seal. Web form fill & seal. In the food and beverage space, our ohlson brand of vertical form, fill. Roll stock is automatically filled, sealed and cut into bags. Premium ffs flat film ; Premium ffs tubular film ; Web vertical form, fill, seal;

First, the machine uses a roll of packaging film that is rolled around a core and typically referred to as rollstock. These machines are designed to facilitate fast and easy changeover of food products and rollstock, as well as deliver a wide range of packaging. Ultra seal ffs flat film ; Web vertical form, fill, seal; It is capable of forming and filling bags measuring 2.5” x 3” to 8” x 14” with volumes ranging from.5 oz to 5 lb, at speeds up to 60 cycles per minute with a pneumatic jaw. Premium ffs tubular film ; Roll stock is automatically filled, sealed and cut into bags. The film is pulled off the roll by belts and is then transferred to a forming tube. It is a highly efficient method that integrates the forming of a package, filling it with a product, and sealing it, all in a continuous and automated production line. Premium ffs flat film ;

FORM FILL SEAL MD

Customized bag sizes contain different material weights and can be used with a wide range of filling equipment for fully automated or. Ultra speed ffs tubular film ; Web form fill and seal operation. Web form fill & seal. First, the machine uses a roll of packaging film that is rolled around a core and typically referred to as rollstock.

Form Fill Seal Machines, फॉर्म फिल सील मशीन at Rs 540000 /piece Form

It is capable of forming and filling bags measuring 2.5” x 3” to 8” x 14” with volumes ranging from.5 oz to 5 lb, at speeds up to 60 cycles per minute with a pneumatic jaw. Roll stock is automatically filled, sealed and cut into bags. But the material comes with several disadvantages, from sustainability issues and limited recycling options.

ZXF0811L2 Form Fill Seal Machine/ Form Fill Sealer Helix Packaging

First, the machine uses a roll of packaging film that is rolled around a core and typically referred to as rollstock. Customized bag sizes contain different material weights and can be used with a wide range of filling equipment for fully automated or. Start your quote features & options features ideal for prepared frozen foods. Premium ffs tubular film ;.

Vertical Form Fill & Seal Packaging and Labelling Equipment and

Roll stock is automatically filled, sealed and cut into bags. Web form fill and seal operation. Ffs offers cost savings over conventional aseptic processing in glass. Web vertical form, fill, seal; Premium ffs flat film ;

Form Fill & Seal Packaging Center USA

Web form fill and seal operation. The film is pulled off the roll by belts and is then transferred to a forming tube. In the food and beverage space, our ohlson brand of vertical form, fill. Ultra seal ffs flat film ; Roll stock is automatically filled, sealed and cut into bags.

FORM FILL & SEAL GOLDPACK

Matrix can help you find your flexible packaging solution. Ultra seal ffs flat film ; Web form, fill, and seal. Ffs offers cost savings over conventional aseptic processing in glass. Premium ffs tubular film ;

Vertical Form Fill Seal

Customized bag sizes contain different material weights and can be used with a wide range of filling equipment for fully automated or. Web form, fill, and seal. Web vertical form, fill, seal; Vertical form fill seal solutions. Heavy duty bags & form fill seal;

Pack tech Ss Horizontal Form Fill Seal Machines, For Industrial

Web form fill and seal operation. It is capable of forming and filling bags measuring 2.5” x 3” to 8” x 14” with volumes ranging from.5 oz to 5 lb, at speeds up to 60 cycles per minute with a pneumatic jaw. The film is pulled off the roll by belts and is then transferred to a forming tube. Start.

Liquid Product FormFillSeal Machine Circle Packaging Machinery, Inc

First, the machine uses a roll of packaging film that is rolled around a core and typically referred to as rollstock. In the food and beverage space, our ohlson brand of vertical form, fill. It is capable of forming and filling bags measuring 2.5” x 3” to 8” x 14” with volumes ranging from.5 oz to 5 lb, at speeds.

ERCA Form Fill Seal

Automatic weighing/filling & packing for free flow powders, granules, bakery products, irregular objects, as well as liquids like icicles, juices, and sauces. Ultra tough ffs tubular film ; In the food and beverage space, our ohlson brand of vertical form, fill. Web vertical form, fill, seal; The most versatile on the market this solution is suitable for all commercially available.

In The Food And Beverage Space, Our Ohlson Brand Of Vertical Form, Fill.

Web form, fill, and seal. Web form fill & seal. Ultra seal ffs flat film ; First, the machine uses a roll of packaging film that is rolled around a core and typically referred to as rollstock.

Our Hamer Brand Of Large Format Horizontal Form, Fill & Seal Bagging Automation Has Set The Industry Standard For Over 30 Years.

Matrix can help you find your flexible packaging solution. It is a highly efficient method that integrates the forming of a package, filling it with a product, and sealing it, all in a continuous and automated production line. Vertical form fill seal solutions. Stickpack & sachet packaging solutions.

Web Heavy Duty Bags & Form Fill Seal.

Ffs offers cost savings over conventional aseptic processing in glass. Roll stock is automatically filled, sealed and cut into bags. Premium ffs flat film ; Web vertical form, fill, seal;

Customized Bag Sizes Contain Different Material Weights And Can Be Used With A Wide Range Of Filling Equipment For Fully Automated Or.

Automatic weighing/filling & packing for free flow powders, granules, bakery products, irregular objects, as well as liquids like icicles, juices, and sauces. But the material comes with several disadvantages, from sustainability issues and limited recycling options to health and safety concerns. It is capable of forming and filling bags measuring 2.5” x 3” to 8” x 14” with volumes ranging from.5 oz to 5 lb, at speeds up to 60 cycles per minute with a pneumatic jaw. The most versatile on the market this solution is suitable for all commercially available resins, such as ps, pp, pet and pla.